Digital Print Optimized Textile Substrate Fiber Market to Reach USD 2.8 Bn by 2036 as Digital Textile Production Scales

Qualification-led print line performance drive the USA digital print textile fiber market, supporting stable ink behavior, repeatability and 7.7% CAGR adoption.

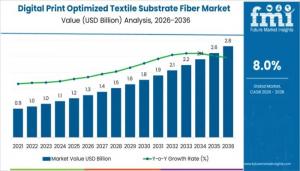

NEWARK, DE, UNITED STATES, January 21, 2026 /EINPresswire.com/ -- The global Digital Print Optimized Textile Substrate Fiber Market is valued at USD 1.3 billion in 2026 and is projected to reach USD 2.8 billion by 2036, expanding at a compound annual growth rate (CAGR) of 8.0% over the forecast period. The market’s expansion reflects the growing role of digital textile printing across apparel, home décor, soft signage, and short-run production programs, where predictable print quality and production efficiency are operational priorities rather than aesthetic upgrades.

Digital print optimized textile substrate fibers are engineered to support controlled ink absorption, edge sharpness, and stable color yield in digitally printed fabrics. Their adoption is closely linked to print system qualification processes maintained by print houses, textile mills, and equipment vendors. Once qualified, these fibers become embedded within defined print platforms, making replacement decisions infrequent and tightly controlled.

Discover Growth Opportunities in the Market – Get Your Sample Report Now

https://www.futuremarketinsights.com/reports/sample/rep-gb-31612

Key Market Facts at a Glance

• Market Value (2026): USD 1.3 billion

• Forecast Value (2036): USD 2.8 billion

• Forecast CAGR (2026–2036): 8.0%

• Leading Fiber Type: Polyester and blends

• Leading Printing Technology: Sublimation digital printing

• Key Growth Regions: China, United States, Germany, South Korea, Japan

Market Context: Why Digital Print Optimized Fibers Matter

Digital textile printing places strict technical demands on fabric substrates. Ink interaction, fixation behavior, and dimensional stability directly influence print yield, machine uptime, and rejection rates. As a result, digital print optimized textile substrate fiber is treated as a process control input, not a decorative enhancement.

Evaluation criteria focus on:

• Ink absorption profiles and dot gain behavior

• Surface uniformity and coating compatibility

• Dimensional stability during drying, fixation, and washing

• Consistency across production lots and fabric widths

Because printer profiles, color management systems, and finishing routes are built around specific substrate behaviors, adoption occurs at the fabric platform level. Volume growth follows the expansion of digital print lines and standardized workflows rather than frequent material switching.

Growth Forecast Through 2036

Between 2026 and 2036, market value growth from USD 1.3 billion to USD 2.8 billion is driven by wider use of digital-first production models. Apparel, home textiles, and signage producers increasingly rely on short runs, customization, and on-demand manufacturing, where repeatable first-pass yield and stable color reproduction are critical to profitability.

Commercial momentum reflects:

• Increased utilization of digital printer fleets

• Longer program commitments tied to approved substrate libraries

• Higher substrate share in print-intensive fabric categories

• Platform standardization across multiple production sites

Annual market values are expected to move through the low- to mid-USD 2 billion range in the early 2030s as digital printing becomes integrated into core fabric collections.

How Optimized Fibers Support Image Stability and Production Yield

Digital printing exposes any inconsistency in fabric behavior. Optimized substrate fibers are selected to control ink drop placement, limit spread, and ensure fixation stability before color management adjustments are applied.

Print operators and mills assess fibers based on:

• Surface energy and capillary control

• Linting, dust release, and fiber protrusion

• Shrinkage, cockling, and edge distortion during fixation

• Wash and rub fastness after printing

Production planning prioritizes machine uptime and reprint avoidance. Substrates that trigger frequent head cleaning, profile changes, or geometric distortion reduce usable press hours and disrupt delivery schedules. As a result, demand concentrates among operations where predictable output and low defect rates determine contract retention.

Market Segmentation Highlights

By Fiber and Fabric Type

• Polyester and blends (≈34% share):

Anchor high-volume digital programs due to controlled dot formation, rapid fixation, and stability in sublimation workflows.

• Cellulosics (cotton and viscose):

Used in direct-to-fabric printing where tactile qualities and artistic range are prioritized, with additional pretreatment steps.

• Nylon and technical fibers:

Support soft signage, flags, and performance fabrics requiring precise handling and thermal control.

• Other substrates:

Remain application- and equipment-specific.

By Printing Technology

• Sublimation digital printing (≈36% share):

Favored for fast throughput, clean fixation, and stable performance on polyester platforms.

• Direct-to-fabric inkjet:

Serves cotton and viscose applications with deeper tones and tactile goals.

• Hybrid and transfer systems:

Provide flexibility for mixed-material ranges and short runs.

Regional Demand Patterns

Growth rates reflect how digital printing platforms are governed and scaled across regions:

• China (9.2% CAGR):

Driven by replication of validated print programs across multiple sites and large-scale capacity additions.

• United States (7.7% CAGR):

Shaped by printhead qualification protocols and demand for customization and rapid sampling.

• Germany (7.6% CAGR):

Guided by centrally managed approval lists applied across distributed manufacturing networks.

• South Korea (7.2% CAGR):

Supported by platform-based substrate definitions influencing multiple product families.

• Japan (6.5% CAGR):

Characterized by disciplined validation cycles emphasizing shade reproducibility and process stability.

Competitive Landscape

Competition in the Digital Print Optimized Textile Substrate Fiber Market centers on print performance reliability rather than breadth of catalog offerings. Suppliers compete during fiber development, pilot trials, and printing line validation, with long-term positioning secured through consistent lot performance and documentation quality.

Key companies profiled include:

• Lenzing AG

• Birla Cellulose (Grasim Industries Limited, Aditya Birla Group)

• Toray Industries, Inc.

• Teijin Limited

• Mitsubishi Chemical Group Corporation

• UNIFI, Inc.

• Indorama Ventures Public Company Limited

• Klopman International S.r.l.

Once incorporated into approved fabric constructions, supplier selection is reinforced by color fastness, filament consistency, and mechanical integrity under digital printing conditions.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Related Reports Insights from Future Market Insights (FMI)

EV Battery Pack Structural Fasteners Market https://www.futuremarketinsights.com/reports/ev-battery-pack-structural-fasteners-market

Oxalic Acid Market https://www.futuremarketinsights.com/reports/oxalic-acid-market

Clear Floor Tiles Market https://www.futuremarketinsights.com/reports/clear-floor-tiles-market

Recarburizers Market https://www.futuremarketinsights.com/reports/recarburizers-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.